| Availability: | |

|---|---|

| Quantity: | |

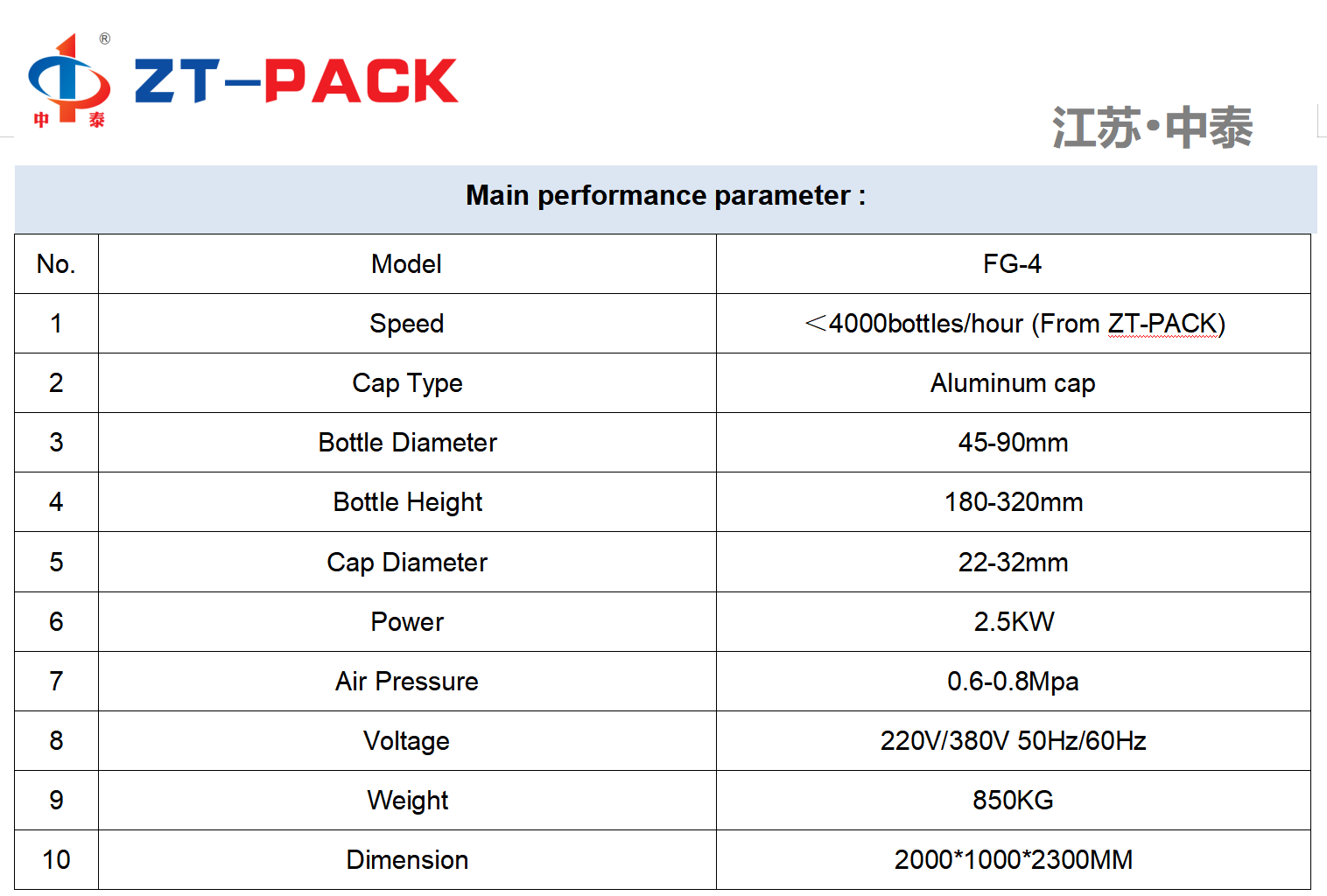

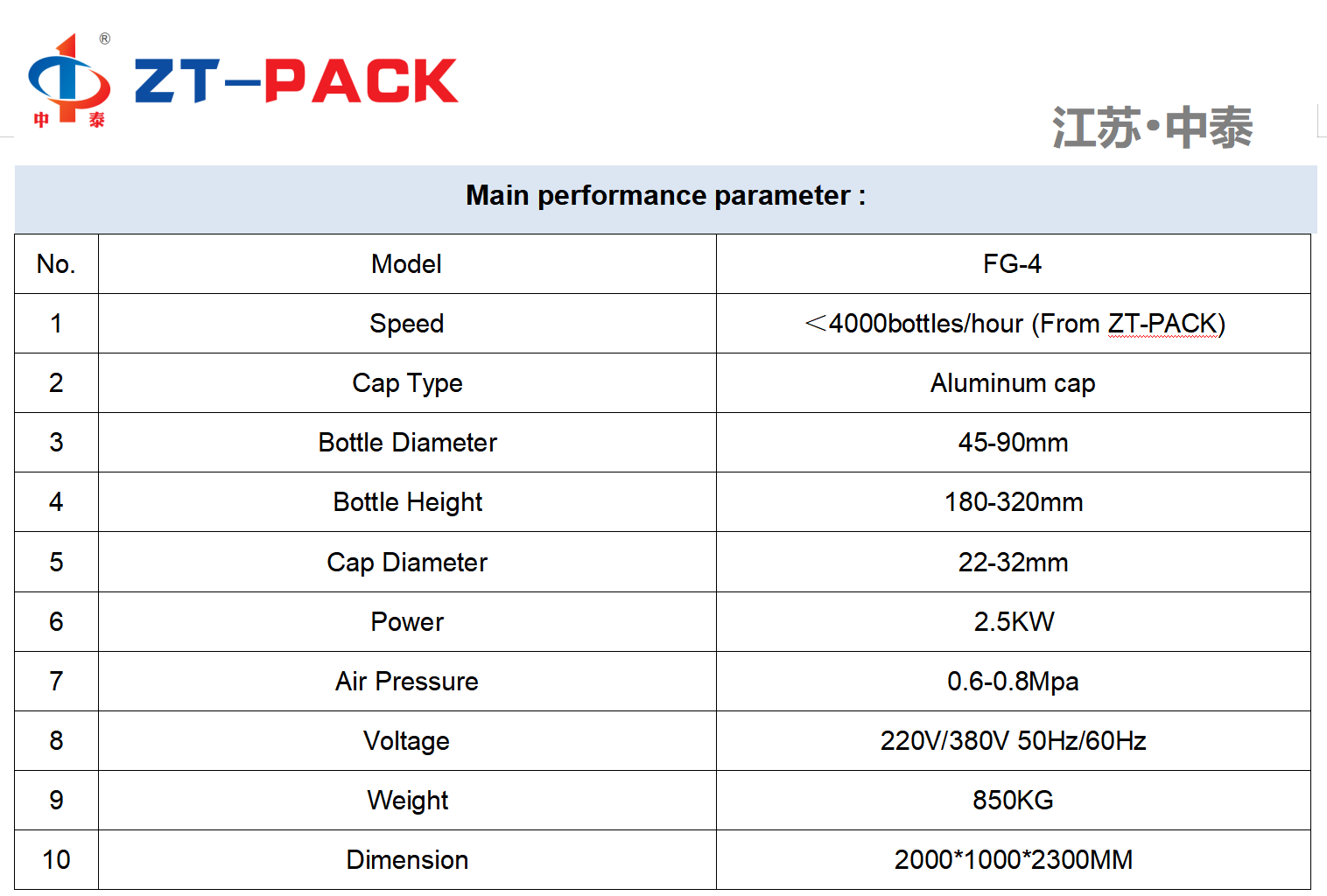

FG-4

ZT-PACK

Machine Name : Full Automatic Rotary Aluminum Cap Screw Capping Machine

Type : FG-4

Suitable For : aluminum caps

Rotary Type

Capacity Speed : 3000-5000BPH

Machine Description :

This Automatic 4 Head Aluminum Cap Crimping Machine is suitable for closing aluminous caps like pilfer- proof aluminous caps.

PLC control system, rotary type structure, the machine is with function of automatic cap feeding ,loading and closing.

The crimping head is made up by strong stainless steel, by 4-wheel balance principle design, the crimping force is uniformly which makes good sealing effect.

Bottle feeding star wheel equip with clutch device, machine stops automatically if bottle get stuck.

And there is automatic positioning device for bottle neck which assure the capping accuracy and stability.

The containers are fed onto the rotary screw capper and are separated and positioned on individual capping stations. The caps are presorted and fed on the sliding table of the machine. The continuously rotating chucks are lowered over the cap to pick up and secure the caps, then apply the caps to the containers. When the preset applied torque value is achieved, the magnetic clutch disengages, the chuck releases the cap and the closed container is discharged from the machine.

With 4 mechanical hands ,the mode is suitable for multi-geometry containers,It bispatches caps at fast speed without any cap reversed . Supplying cap system and mechanical hands work together in phase . When the cap is tightened , bottle and cap stand still relatively ,and the clutch separates immediately so that able and not apt to be damaged .

Suitable for caps :

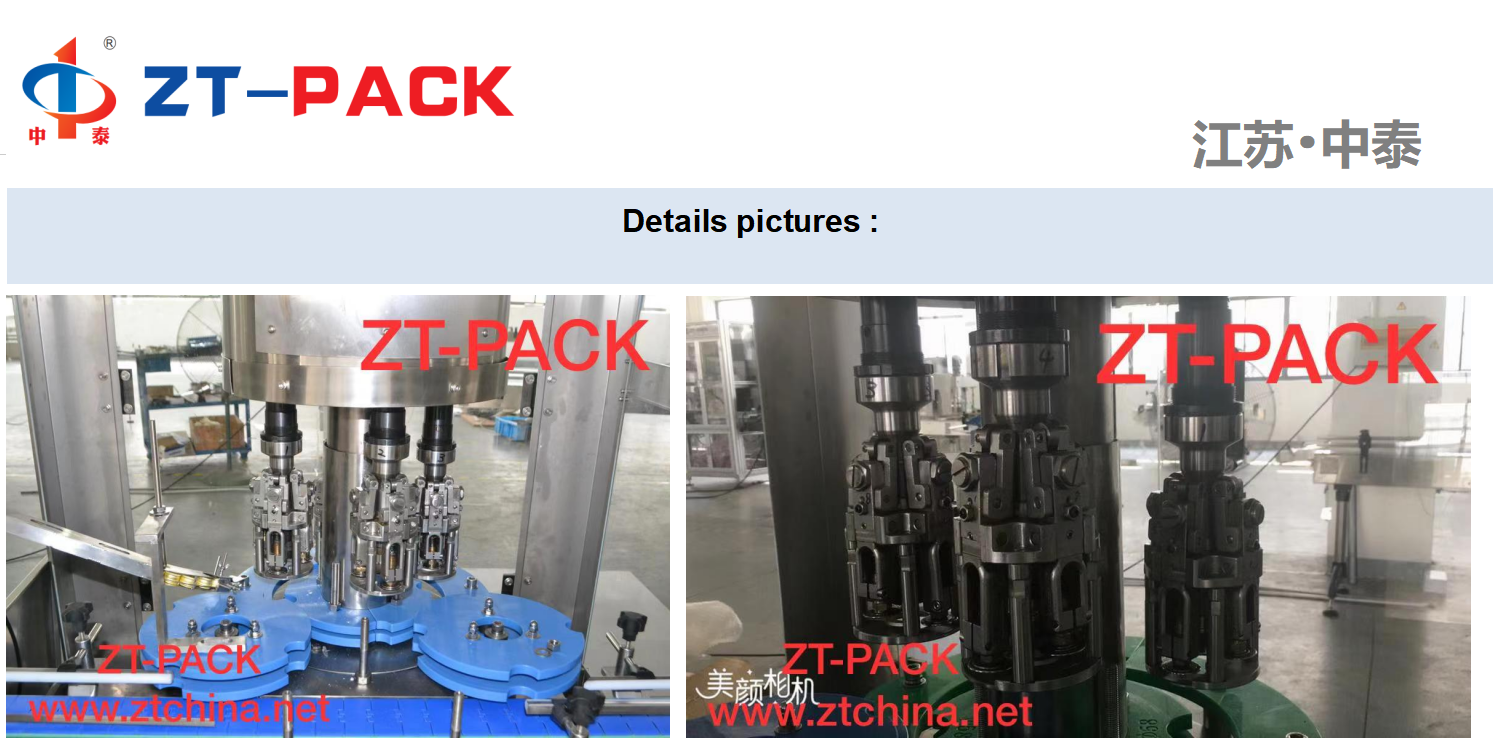

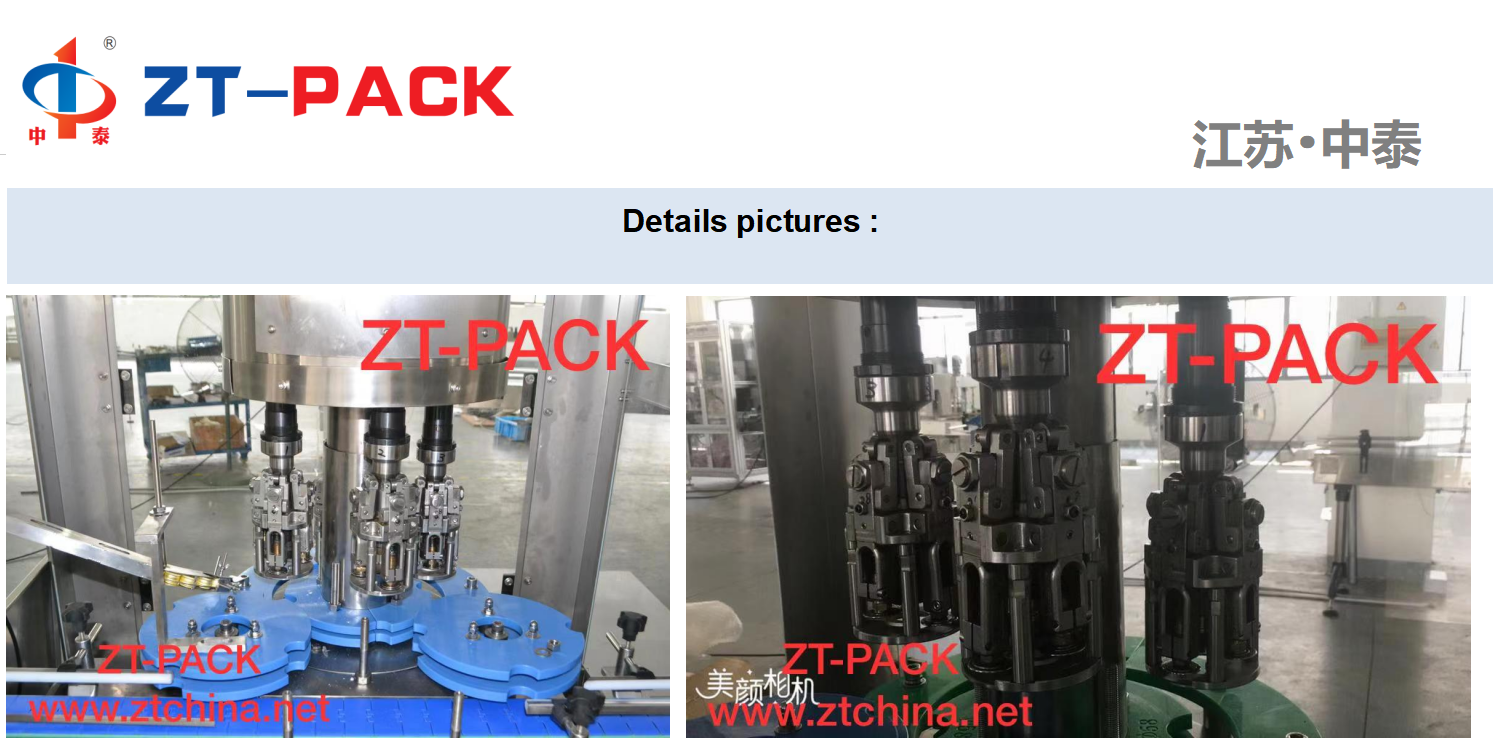

Details Pictures :

Carbon steel base mounted on adjustable floor levellers for easy alignment

Bearing frame and all surface components manufactured in 304 stainless steel

Magnetic clutch capping heads for screw caps complete with pick & place cap system

Caps in chute photocell, machine will not work if there are no caps present on chute

Automatic cap feeder, chute and applicating head

Electrical socket for optional elevator feed

Safety guarding with interlock devices

Cap change parts complete set to run a different size cap(option)

Cap elevator to load the cap feeder automatically(option)

Machine Name : Full Automatic Rotary Aluminum Cap Screw Capping Machine

Type : FG-4

Suitable For : aluminum caps

Rotary Type

Capacity Speed : 3000-5000BPH

Machine Description :

This Automatic 4 Head Aluminum Cap Crimping Machine is suitable for closing aluminous caps like pilfer- proof aluminous caps.

PLC control system, rotary type structure, the machine is with function of automatic cap feeding ,loading and closing.

The crimping head is made up by strong stainless steel, by 4-wheel balance principle design, the crimping force is uniformly which makes good sealing effect.

Bottle feeding star wheel equip with clutch device, machine stops automatically if bottle get stuck.

And there is automatic positioning device for bottle neck which assure the capping accuracy and stability.

The containers are fed onto the rotary screw capper and are separated and positioned on individual capping stations. The caps are presorted and fed on the sliding table of the machine. The continuously rotating chucks are lowered over the cap to pick up and secure the caps, then apply the caps to the containers. When the preset applied torque value is achieved, the magnetic clutch disengages, the chuck releases the cap and the closed container is discharged from the machine.

With 4 mechanical hands ,the mode is suitable for multi-geometry containers,It bispatches caps at fast speed without any cap reversed . Supplying cap system and mechanical hands work together in phase . When the cap is tightened , bottle and cap stand still relatively ,and the clutch separates immediately so that able and not apt to be damaged .

Suitable for caps :

Details Pictures :

Carbon steel base mounted on adjustable floor levellers for easy alignment

Bearing frame and all surface components manufactured in 304 stainless steel

Magnetic clutch capping heads for screw caps complete with pick & place cap system

Caps in chute photocell, machine will not work if there are no caps present on chute

Automatic cap feeder, chute and applicating head

Electrical socket for optional elevator feed

Safety guarding with interlock devices

Cap change parts complete set to run a different size cap(option)

Cap elevator to load the cap feeder automatically(option)

WhatsApp : +86-13685270809

Mobile Phone : +86-13685270809

Tel/Fax:+86-519-82113618

Email : zt-pack@hotmail.com

395377419@qq.com